- Serialisation

- DataMatrix and Barcodes

- RFID

- IoT

- Remote Monitoring

- Supply Chain

- Consultation

- Industries

Need Help?

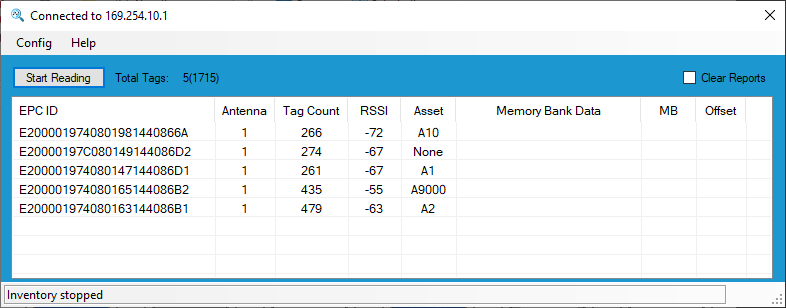

Serialogical have developed solutions for UHF RFID tag reading and writing. UHF tags can be accessed at distances of approximately 4m and unlike printed barcodes do not depend on a line of sight to the reader.

Each UHF tag is created with a unique immutable code (the tag id; TID) and has an additional code (the electronic product code; EPC) which can be modified by the user. The TID code is best used for product serialisation as each tag and attached product will be unique. The EPC code is often set to a product ID with all instances of a product item sharing the same code.

A ‘single’ scan will read tags multiple times. By a combination of the TID and EPC data the scanner knows how many of each product are seen in a scan. Tags also allow some additional user data to be stored within the tag but this volume is so small that it is best to look up the TID or EPC in a separate information system to gain more details about the tagged items.

Bundled commercial reader software takes the data read and presents it to the user. Serialogical have created programmed solutions to access this data and manipulate it for subsequent business analysis.

Implementations include:

- Products in a monitored area currently or at set time intervals.

- Movement of products into or out of a monitored area.

- Tracking of products within a chain of monitored areas.

- Filtering of monitored tags from rogue RFID tags (tags not currently in use but picked up by the reader).

- Details of box contents where a single tag labels a box of multiple products.

- Aggregation of tags within a shipment.

Serialogical can store the data collected from RFID readers on a network local to each reader. Additionally we can send data to remote internet servers allowing a comparison of data between multiple sites.

Serialogical take the read tags and identify those corresponding to stock items. Data is uploaded to a remote database for subsequent processing.

A single tag can be linked to the items within the labelled entity. This might be the packs contained within an aggregate container. In FMD this can be used to track a set of product codes and retreive the individual codes for verification or other processing as a bulk file.

Tags can also be linked to IoT data such as location and environmental variables. Access to historical data allows tagged items to be monitored over time and trends analysed from a central web-based interface.