How the pharmacist can work with prescriptions in FMD

The combination of serial number, product code, batch number and date is unique for each FMD labelled packet. This means that having access to one or more packets even within the same batch will not enable any other codes to be calculated. The concept of aggregation is used in packing to ensure that a group of codes can be identified. An example use would be labelling a box outer so that all the packs within that outer can be identified. This is not directly possible within FMD without including full details of all packets on the outside of the container they are housed in. Even if the entire contents of the batch were in a single container it is not permitted to order or sequence the codes. The system will never know the identity of the first and last tag nor the number of codes in a batch. Wholesalers are allowed to send a set of codes from the same batch to the NMVS. They must send up the product code, batch and expiry (once) and the serial number of every pack within that batch to be checked. This process is not available to pharmacists.

There is a demand for some degree of goods aggregation from the pharmacist but that has to work within the constraints of the FMD. The solution, sometimes called ‘baggregation’ is to organise virtual sets of packets. When a pack is scanned the result of the scan is noted and if it is live the pack details are recorded and added to a virtual bag. Several packs can be added to the same virtual bag or removed from the bag. A pack cannot be added to more than 1 bag and if the virtual bag is ‘destroyed’ the packs are removed from the bag. This system allows the virtual bag to be recalled as a set and then that set of codes can be sent to the NMVS for verification, decommissioning or un-decommissioning. An application would be to have the virtual bags correlate to real prescription bags for a patient. This solution gives the pharmacist the option to only scan individual packs once but with a check on the pack status through the NMVS at the time of dispensing. Not all packs need to be in a bag; for example when a pack is split amongst several prescriptions. It would then be, individually, decommissioned when the pack seal is first broken.

The products are scanned and verified as the bag is made up. The bag can later be verified again, decommissioned or un-decommissioned and the action will apply to all the packs within the bag. This action is permitted by the NMVS using the mixed bulk activity which allows a mixture of FMD codes to be sent up as a set and does not depend on all the codes being from the same batch. The act of decommissioning includes an element of verification so if the whole bag is decommissioned the NMVS will report back on successful or unsuccessful decommissions.The pharmacist would benefit by only needing to scan individual codes once, subsequently relying on sending the virtual bag contents to the NMVS. The NMVS has no knowledge of which packs are physically within the set.

There are some caveats to any operation of this type:

• It is part of the dispenser’s role to ensure that the correct bag is dispensed to the correct patient.

• The dispenser must ensure that the correct pack is put in the correct bag as the pack is scanned and the bag is filled. It is not sufficient to have the correct product in the correct bag.

• The details of packs within a virtual bag need to be recorded not necessarily the results of their scans. The state of a pack can be changed outside the dispenser. For example it might be set to stolen or recalled after the dispenser scanned it. Events of this type will be picked up when the bag is decommissioned.

• The contents of an entire bag could be decommissioned but the 10 day window for un-decommissioning will apply to all packs within that bag.

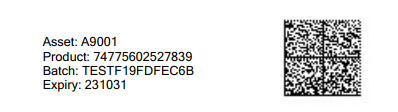

The final issue is identifying the bag. At Serialogical we automatically create a bag id when it is created and optionally allow a bag to be named. For example bag 265 is ‘Mrs M Jones’. The code can then be written on the bag and used to retrieve the codes within, the name and date created being an additional check. An alternative is to create a new code for the bag. In programming terms this is not an obstacle. In operation the dispenser would need a dedicated label printer or scissors and glue